CIRCULAR CASE 4

Chemical sector

Sweden

How to integrate a mountain of fibre waste into an industrial symbiosis complex.

Current situation/ Problematic addressed

The Chemical- and forest industry are two of Sweden’s most important basic industries, accounting for about 20 percent of Sweden’s exports. The competition in the two industries is now exceptional, with the environmental issues related to usage of fossil resources and the falling demand for paper. The forest industry must replace their existing product portfolio with new products while the chemical industry must replace fossil based materials with renewable raw materials.

Domsjö Fabriker is a sulphite mill with production of wood based cellulose mainly for the viscose industry. It produces dissolving pulp (240,000 tons annually), ethanol (17,000 tons annually) and lignosulfonates (120,000 tons annually). As a consequence of these production processes, around 20.000 tonnes of fibre sludge waste coming from the primary waste water treatment are yearly generated. Fibre sludge comprises cellulose and hemicellulose as main constituents. Waste fibre sludge is produced as a side product at most pulp mills and is usually used for internal energy production. This is, however, not the ideal solution due to the low energy content and high moisture of fibre sludge.

Partners involved

Domsjö Fabriker (DOMJSO) (dissolving grade cellulose pulp industry); Develop new cellulose qualities and demonstrate an alternative ethanol production source.

SEKAB: chemical industry handling of ethanol and chemical process knowledge in demonstration of ethyl chloride production.

Azko Nobel (AKZO): user of ethyl chloride, knowledge in chemical process and producer of Bermocoll.

SP Processum (SP): research institute providing knowledge in process and flow chemistry and industrial biotechnology, coordination of the chemical demo.

Circular economy model

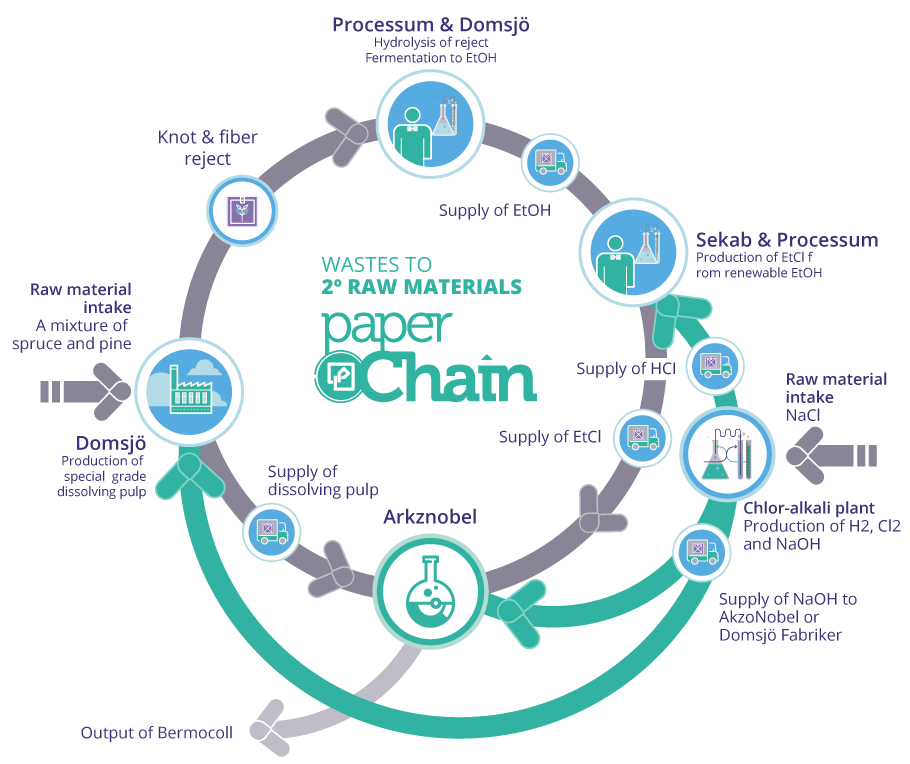

The industrial site in Domsjö, Sweden, is formed by three companies representing the Pulp Industry Domsjö Fabriker (Domjso) and the Chemical industry: Sekab and Akzo Nobel (AKZO). SP Processum (SP) is a research institute that is located at the same site and works with the industries above mentioned.

Residual sugars obtained from the fibre sludge generated by Domsjö Fabriker can be used to increase the production of ethanol. This ethanol can serve as raw material for the local industry SEKAB which has an infrastructure for handling 300,000 tons of renewable ethanol in different types of chemical processes.

In parallel, AKZO consumes annually about 9,000 tons of ethyl chloride for the production of Bermocoll®. The product is built up by high grade cellulose that is chemically substituted with a mixture of ethyl chloride and ethylene oxide to produce a water soluble polymer that is used as a thickener in water based paint and building applications. The current production of ethyl chloride is rather small and entirely dependent on fossil raw materials. In a nutshell, fibre sludge will be used to produce high quality ethanol. Then, this ethanol will be used to produce ethyl chloride. Finally, this ethyl chloride will be used to produce Akzo Nobel’s product Bermocoll, a paint stabilizer.

DEMONSTRATION ACTIVITIES

Due to the high investment needed to accomplish the modification of the production lines, the demo will take place in a fully operative pilot plant owned by the consortium formed by SP, DOMSJO, SEKAB and AKZONOBEL as a necessary way of minimising the technical risks of the investment. The supporting infrastructure is already in place at an ATEX-approved area with general equipment such as a remote control system (Delta V), heating systems, valves, pumps and transducers for measurements of temperatures and pressures.

Main objectives

Hydrolysis and fermentation of fibre sludge by using enzymes for the hydrolysis and yeast for the fermentation. Fibre sludge and hemicellulose in softwood and ordinary baker´s yeast will be used in the fermentation step. Approximately 200 kg of bioethanol will be produced from 500 kg of fibre sludge. Demonstration of continuous production of 15 kg/day of ethyl chloride from renewable ethanol for 3 weeks to demonstrate the continuous production of 300 kg of ethyl chloride.

kg of bioethanol

kg of ethyl chloride

Production

Upscaling validation.

Technical performance:

performance of the produced materials (cellulose, ethanol, ethyl chloride and Bermocoll) will be evaluated. Workability: The new cellulose qualities developed in the project must meet the criteria for being used as component in cellulose ethers; the cellulose has to be delivered on reel that will promote an extension to be built. Several parameters must be checked during the demonstration of ethyl chloride synthesis where effluent streams must be carefully monitored. The ethyl chloride will be analysed regarding purity and possible contaminants. The process impact in the preparation of Bermocoll depending on the quality of ethyl chloride must be established.

Environmental performance:

Waste water and other effluent streams from the different process steps will be analysed to ensure a high environmental performance.

Quantification of the valorisation achieved during the project & Replication potential

During the project:

The demonstration will lead to a business plan for the complete value chain from wood to Bermocoll. Domsjö Fabriker will have an increase in the ethanol production and a more versatile cellulose product. Sekab have the potential to expand their product portfolio with ethyl chloride which will include the construction of a new chemical plant. Akzo Nobel will be able to produce a more sustainable product while also securing the raw material supply of ethyl chloride.

Replication:

Ethanol is a global commodity that is a part of the transition to a bioeconomy in Europe and all sources of raw material for ethanol production have to be considered. Wood based fibres are a highly interesting substitution of cotton linter due to problems with irrigation and use of pesticides in cotton production. Bermocoll and other cellulose ethers are produced at several locations worldwide and could replace fossil based products in additional applications with further development.