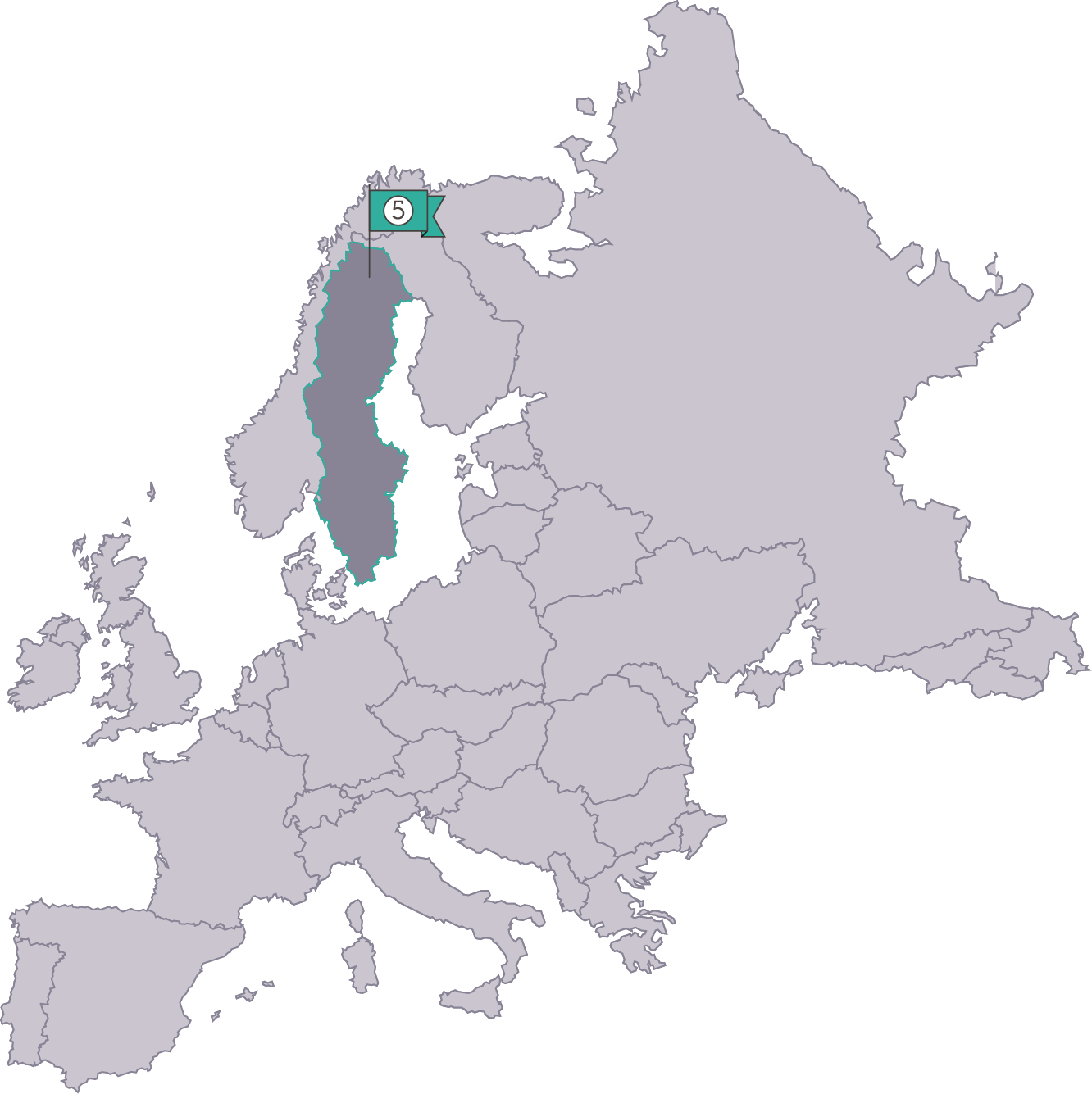

CIRCULAR CASE 5

Mining sector

Sweden

A recycling challenge for the pulp industry (DREGS) as a successful environmental additive for the mining industry

Current situation/ Problematic addressed

Mining generates huge amounts of waste such as rocks (removed rocks to access the ore) and tailings (grinded left over material after processing the ore). The global production of mine wastes was estimated at 15.000 – 20.000 million tons of solid waste each year, a sum greater than the waste produced from all other human activities taken together. The major potential long-term environmental effect of mining is the formation of acid rock drainage (ARD) in sulphide-bearing mine waste, which can last for hundreds or even thousands of years. The common ways to deal with ARD from mine waste are i) to limit water and oxygen infiltration, and ii) to lime the collected effluents in sedimentation ponds, generating huge amounts of potentially toxic sludge. To limit water and oxygen infiltration, waste rock is covered with borrow materials available on site, normally clay and glacial till, which frequently do not possess the best sealing capacities and implies the use of thicker layers of sealing materials, leading to economic and environmental overruns.

Meanwhile, GLDs are the largest waste fraction retrieved in the chemical recovery cycle at the sulphate pulp mills. Approximately 240.000 tonnes are landfilled in Sweden each year because their only current relevant application is as diary landfill cover layers.

Partners involved

SP-Processum (Research Institute): Case Study coordination, material characterization and monitoring.

LTU (University): Demo planning and evaluation. Support for dimensioning, testing and monitoring of the heavy metals content and their mobilization in the hydrogeological model at Boliden´s waste rock deposit.

Boliden Mineral (Mining company): Site provision, technical assistance in relation with mining procedures and requirements for soil covers, mining waste provision and handling recommendations.

Supporting parties:

- Waste Manager: RagnSells will manipulate GLDs and build the demonstrator

- Pulp and Paper Industry: BillerudKorsnäs. Provision of GLDs.

Circular economy model

The mining sector can benefit from GLDs as alternative material for covers to reduce raw material consumption in their reclamation projects. At the same time, the PPI could find a new market niche to valorise a waste product which is currently disposed of, solving two waste problems at the same time. For this purpose, the Technological University of Lulea (LUT), along with SP Processum (SP) and the cooperation of the involved industrial sectors, Boliden and a Swedish Paper Industry, have developed a strategy to more efficiently utilise the properties of GLDs to mitigate the negative effects of ARD. Since landfilling is costly, re-using this material would provide remarkable savings for the PPI.

Through an intense laboratory testing and an ongoing field trial they have proved the positive effects of mixing glacial till with a low percentage of GLDs to improve their properties as soil covers. Demonstration activities are needed to validate the function of the alternative materials before they can be used at industrial scale. In particular, reliable predictions of the long-term efficiency are crucial. In this sense, PAPERCHAIN proposes to demonstrate the feasibility of this technology at industrial scale by the construction and monitoring of a large-scale demonstrator.

DEMONSTRATION ACTIVITIES

Demonstration

The main objective will be to demonstrate and optimize the use of GLDs as sealing layers for mine waste deposits. Research performed by the members of the consortium has shown the advantage of using GLDs. However, laboratory and pilot experiments do not permit optimize full-scale production. This demo will get evidence to propose an efficient method to produce and built GLDs-based sealing layers.

Based on previous results, guidance for characterization and definition of mixing recipes has been developed along with a method for mixing and compacting the sealing layers. This guidance can be tested in a real environment, a 4.4 Ha waste rock landfill in Northern Sweden that Boliden executed on summer 2017 to carry out the preliminary monitoring activities. Given its innovative character, no information is available on the robustness of the sealing layer for its sizing, so that, a large safety factor has been used for the construction work regarding the mixing process, the compaction, and the thickness, in order not to take any environmental risk. As a consequence, the solution is oversized and has to be optimized by reducing safety factors to reach the market.

The main objective will be to demonstrate and optimize the use of GLDs as sealing layers for mine waste deposits. Research performed by the members of the consortium has shown the advantage of using GLDs. However, laboratory and pilot experiments do not permit optimize full-scale production. This demo will get evidence to propose an efficient method to produce and built GLDs-based sealing layers.

Monitoring of the pilot at the mine site provided by Boliden Mineral, where a GLD/till mixture will be used as sealing layer. The effect of aging on the barrier function of the layer will be studied during the first two years of the project to identify uncertainties about the technology. The monitoring will result in the definition of new specifications for the demo, including the optimisation of the layer thickness.

Construction of a 500 m2 demonstrator to optimise cover construction at the Boliden´s Aitik mine.

The demonstration comprises three steps:

- i) optimisation of mixing using e.g. in-situ mixers,

- ii) comparison of different compactors and

- iii) assessment of the barrier function of sealing layers (0.2-0,5 m) and protective layer (0.3 – 1.5 m) with varying thickness.

Assessment and follow-up of the demonstration site to measure, water content, oxygen transport and temperature within the layers. The conclusions of the assessment will serve to update the guidance for construction of sealing layer for mine waste deposits.

The following activities will be carried out

Monitoring of the pilot at the mine site provided by Boliden Mineral

Construction of a 500 m2 demonstrator

Assessment and follow-up

Technical performance:

The pilots will be monitored to test durability, quality and technical performance over the long term. Laboratory and field tests will be carried out to control KPIs required to fulfil the function for mine waste cover defined in international standards such as Hydraulic conductivity, Water retention capacity and Oxygen diffusion. Workability will be also addressed by monitoring the productivity parameters (i.e hourly productivity ratio of GLD/till mixture)

Environmental performance:

Effect of the leachate (percolating precipitation) on the underlying mine waste and the recipient, monitoring those parameters (metals and anions) according to regional laws.

Quantification of the valorisation achieved during the project & Replication potential

tonnes of GLD valorisation

ton of GLD valorised/year

During the project:

The 500 m2 pilot will lead to the valorisation of 75 tonnes of GLD in the production demo. At the site monitored in the first two years of the project, 3000 ton of GLD are valorised.

Replication:

The global production of mine wastes is estimated at 15.000 – 20.000 million tons of solid waste each year. The consumption of natural resources such as soil and clay to cover this amount of material is huge which open opportunities for GLD utilisation. Boliden operates many other mining operations where the technology can be quickly and easily replicated.